Limit Standard

When visual appearance is critical Master Standards are created. These are generated and approved by the customer and then used by manufacturers as part of their quality control inspection regime. As these Master Standards have been visually approved they often do not have numerical gloss values assigned.

In order to avoid subjectivity between inspectors, the Elcometer 480 can automatically generate and store the nominal (target), highest & lowest acceptable gloss values (Limits) from the Master Standard.

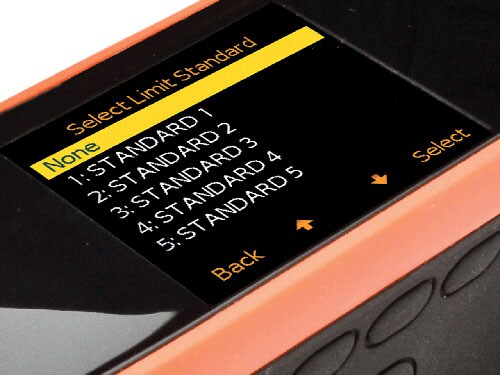

Up to 40 Limits for each customer's Master Standards can be stored within, and recalled from, the gauge's 'Limit Standard' memory.

When Limit Standards are used in combination with the gauge's Differential Mode, the Elcometer 480 displays the measurement value together with the difference from the nominal (target) value.

Readings outside the Limit Standard are displayed in red, providing quick Pass/Fail analysis.

Due to the Elcometer 480's industry leading inter-instrument agreement, once a Master Standard Limit has been created, the gauge can transfer these values to the Library of Limit Standards within ElcoMaster™ and then transfer them to other Elcometer 480 gauges.

Information from multiple glossmeters can be combined into a single inspection report within ElcoMaster™, ideal for multiple production and assembly lines.