|

|

|

Blast Machine Accessories

| From pop up valves and access doors to sieves & lids and moisture separators, Elcometer has an extensive range of accessories for your abrasive blast machine, manufactured out of heavy duty, durable materials. |

Whilst the front leg plates of all Elcometer’s abrasive blast machines have an uncoated base to dissipate static build up, the Elcometer Earthing Wire assembly quickly attaches to the rear of the machine to prevent static electricity build up at the back of the pot.

|

The highly efficient Elcometer Moisture Separator prevents moisture and oil from the compressor entering the blast machine. Eliminating up to 98% of the moisture and oil from compressed air, the moisture separator stops the abrasive becoming damp and clogging the blast machine.

As the Elcometer Moisture Separator is rated to a working pressure of 15bar (217psi), it does not have a glass viewing area, this ensures it will not break under pressure.

|

Elcometer SOV Abrasive Media Shut Off Valve stops the flow of abrasive so you can service your media valve without wasting abrasive.

- Easy to fit to all Elcometer abrasive blast machines (excluding the Elcometer 1020) using automatic or general media valves - simply screw into pot coupling

- Shuts off the flow of abrasive at any time, even when the machine still contains abrasive, to allow you to service the media valve or replace the rubber liner

- Easily serviced - simply take out the split pin and remove the valve

|

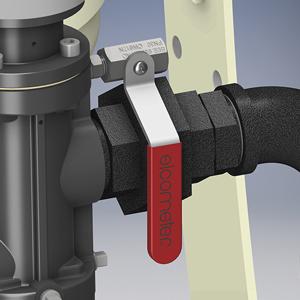

Designed with a large, easy to reach handle, the red Elcometer safety petcock valve fits to the Elcometer RCV4000 and RCV4000+ remote control valves. In an emergency it will isolate the deadman’s handle circuit and depressurise the blast machine quickly.

|

Air Supply Ball Valves are fitted between the air hose and the moisture separator to isolate the compressor when undertaking maintenance work - disconnects the compressed air from the blast machine for safe work.

|

The Elcometer Magnetic Sweeper will collect steel shot and other magnetic items including: nails, screws, nuts, bolts, pop-rivet studs, wire off-cuts, punchings and any other ferrous waste materials.

- Ideal for either internal or external use, clearing workshops or yards, in any weather, even standing water

- Built around a substantial aluminium casting, the powerful permanent anisotropic magnets collect waste at a brisk walking pace

- Adjustable height, large front wheels and rear castor allows the unit to be extremely manoeuvrable and able to cope with bulky waste and uneven surfaces

- A handle-operated release mechanism drops the waste into a neat pile which can then be swept up, using the integrated collection tray and brush

- Available in two widths

|

Manufactured from metal, the Elcometer abrasive blast machine pot couplings are heavy duty and durable. Available in a range of sizes, they allow an easy connection of the blast hose to the abrasive metering valve.

|

Elcometer’s abrasive blast machines make inspection and servicing easy, thanks to the large access doorway which is wide enough for both of your arms.

Each door comes with an ElcoFit™ wrap-around sealing gasket so you don’t have to worry about gasket alignment when closing up.

- Large doorway access fits both arms - ideal for servicing

- ElcoFit™ wrap-around sealing gasket makes door alignment easy and fast

- Quickly replace the yoke and nut if threaded, as the parts can be easily sourced

|

The Elcometer Internal Pop Up Valves ensure fast pressurisation of Elcometer blast machines. The automatic pressure sealing pop-up valves are fitted with reinforced metal guards, making them incredibly hard-wearing.

|

Available as a user fitted accessory, the protection skid provides unparralleled protection of the valves and pipework of Elcometer abrasive blast machines.

Ideal for providing complete protection for your valves and pipework, especially when loading and unloading your machine.

Suitable for use with the Elcometer 1440, 1460 & 20100 abrasive blast machines.

|

Pressure relief valves must be incorporated into the blast machine system to meet global safety standards. Elcometer’s certified pressure relief valves can be easily fitted to the air manifold which is fitted to the RCV4000+ remote control valve. Pressure relief valves are designed to discharge the compressed air in the blast machine upon reaching the crack pressure.

|

Manufactured from durable 1/4” (6mm) high quality steel for years of use, Elcometer’s blast machine lids & sieves are specially designed to sit outside the rim of the blast machine to prevent water ingress.

Available in a range of sizes to fit all Elcometer blast machines, they can be purchased individually, as a set or as part of the Elcometer blast kits.

|

Manufactured from durable 1/4” (6mm) high quality steel for years of use, Elcometer’s blast machine lids & sieves are specially designed to sit outside the rim of the blast machine to prevent water ingress.

Available in a range of sizes to fit all Elcometer blast machines, they can be purchased individually, as a set or as part of the Elcometer blast kits.

|

|

|

|

|

|