|

|

|

Coating Inspection

| With a range of products specifically developed to meet the needs of the coatings industry, Elcometer is well positioned to provide you with the solution to your inspection requirements - whatever and wherever they might be.

The coating process requires inspection at every stage to ensure compliance to the specification. From the preparation of the surface to be coated, through climatic condition monitoring to the dry film thickness evaluation, visual assessment and gauge-based testing will ensure adequate process control.

For steel surface preparation, the removal of rust and other contamination and the creation of a surface profile is required to enhance the adhesion of the applied coatings. Elcometer offer a range of visual standards for rust removal and a simple test for dust on blast-cleaned surfaces. In order to determine the level of soluble salt contamination of the blast cleaned surface, a range of salt contamination methods are available including the Bresle Patch Method, the Saturated Filter Paper method and the chloride-specific titration tube method.

For climatic condition monitoring Elcometer offer simple bi-metallic magnetic thermometers and electronic thermometers for temperature measurement, with wet and dry bulb hygrometers and electronic dewpoint meters for the measurement and data-logging of relative humidity and dewpoint temperatures. Oven temperature logging and wind velocity measurement are also available.

For coating thickness Elcometer offer wet film combs, mechanical and electronic non-destructive dry film thickness gauges, the destructive paint inspection gauge and the non-contact powder coating thickness gauge.

For post coating assessment of adhesion and porosity of the coating there is a full range of adhesion testers and low and high voltage holiday detectors. |

Knowing the coating thickness of dry film is a critical measurement in the coating application process. It provides vital information as to the expected life of the substrate, the product's fitness for purpose, its appearance and ensures compliance with a host of International Standards. For more than 6 decades, Elcometer have been world leaders in coating inspection and coating thickness measurement, offering a wide range of accurate digital and mechanical dry film thickness gauges. Elcometer's latest innovation, the new Elcometer 456 sets new standards in coating thickness measurements. Available in a range of models for measuring dry film thickness on ferrous & non-ferrous metal substrates, the new Elcometer 456 is even more powerful, rugged and easier to use than ever before.

|

The monitoring of climatic conditions such as temperature, relative humidity, dew point and moisture in industry is often vital to the success of the application of a coating. These parameters determine both the conditions for the application of the coating, and the resulting quality and performance of the coated product. In the protective coatings industry, moisture can form on the surface when the surface temperature is low enough to cause condensation from the atmosphere. The dewpoint temperature (Td) is the point at which this occurs. The temperature of the coating material is also important as temperature affects the coating′s shelf life, viscosity and its application characteristics.

|

The degree of profile on the surface affects a coating’s overall performance and determines aspects such as adhesion, coverage and overall volume of coatings used. If the profile is too large the amount of coating required increases, otherwise there is a danger that the peaks remain uncoated – allowing rust spots to occur. If the profile is too small there may be an insufficient key for adequate adhesion. Find out more information on Surface Profile Inspection.

|

Surface contamination comes in many forms and Elcometer offers a complete range of products to comply with your testing specification. Our most popular test kits are those that quantify salt levels. Salts are comprised of chlorides, sulfates, and nitrates - which all contribute to the conductivity of a solution. Elcometer offers several conductivity testing kits including our newest instrument, digital Elcometer 130 Salt Contamination Meter, and the Bresle path method.

|

Measuring coatings before they have cured can predict the final film thickness.

Applying too much coating not only wastes time and materials, it can also affect the performance and finish of the product. Too much wet film can cause the coating to crack as it cures; too little coating increases the risk that the substrate will not be sufficiently protected, leading to rust spots.

In the powder coating industry, ensuring the end product has the correct levels of adhesion and appearance is dependent on the thickness of the powder prior to the curing process. Too much powder can lead to poor adhesion, too little can lead to a discoloration and loss in gloss of the coating.

|

Adhesion testers verify that both surface preparation and coating application are within specification.

From the largest man-made structures to the smallest household appliances, most manufactured products have a protective or cosmetic coating. Premature failure of this coating can, at the very least, result in additional costs of rework.

|

Suitable for thinner coatings the wet sponge method can easily identify the location of coating defects.

|

Elcometer offers one of the widest ranges of inspection equipment available. Our products are used across numerous industry sectors. In all cases, there is always a need to undertake a number of specific inspections during quality control assessments - as one parameter can affect another. For example, the thickness of an applied coating can affect properties such as adhesion, gloss, color and porosity. Elcometer has put together a series of industry and product specific inspection kits - combining a number of gauges from our range. Each kit is supplied in a convenient sturdy plastic carry case, ideal for transporting to and from the inspection site.

|

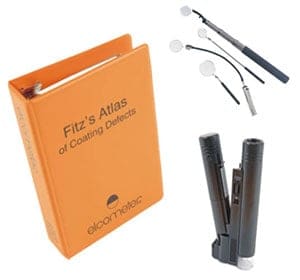

Range of equipment to support your inspection analysis, from comparison manuals through to microscopes and flashlights.

|

|

|

|

|

|