|

|

|

Glossmeters

|

The ability of a surface to reflect light without scattering is known as gloss. Gloss is measured by directing a constant intensity light beam at a fixed angle to the test surface and then by monitoring the amount of reflected light at the same angle. Different surfaces require different reflective angles. Elcometer Glossmeters cover the range necessary to measure almost any surface from high gloss to matt, from large to small surfaces, flat or curved.

|

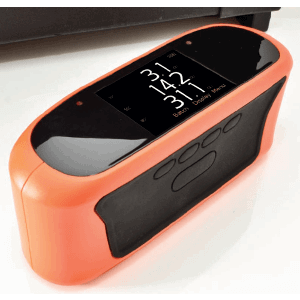

The Elcometer 480 range are easy to use glossmeters which combine high accuracy, repeatability and reproducibility with functionality making them the most advanced glossmeters on the market today. Small, robust and ergonomic, the Elcometer 480 range of glossmeters have been designed to exceed the demands of industry today. Combining easy to use, multi-lingual menu structures with exceptional repeatability, reproducibility & accuracy, the Elcometer 480 provides users with best in class hand held gloss measurement.

|

The Elcometer 480 range are easy to use glossmeters which combine high accuracy, repeatability and reproducibility with functionality making them the most advanced glossmeters on the market today. Small, robust and ergonomic, the Elcometer 480 range of glossmeters have been designed to exceed the demands of industry today. Combining easy to use, multi-lingual menu structures with exceptional repeatability, reproducibility & accuracy, the Elcometer 480 provides users with best in class hand held gloss measurement.

|

The Elcometer 480 range are easy to use glossmeters which combine high accuracy, repeatability and reproducibility with functionality making them the most advanced glossmeters on the market today. Small, robust and ergonomic, the Elcometer 480 range of glossmeters have been designed to exceed the demands of industry today. Combining easy to use, multi-lingual menu structures with exceptional repeatability, reproducibility & accuracy, the Elcometer 480 provides users with best in class hand held gloss measurement.

|

Small, robust and ergonomic, the Elcometer 480 range are easy to use glossmeters which combine high accuracy, repeatability and reproducibility with functionality making them the most advanced glossmeters on the market today.

|

|

|

|

|

|