|

|

Automatic Pull-Off Adhesion Tester | 20mm Kit | Model S | Elcometer 510

Price: $2,999.00

SKU: F510-20S

Please allow 2-4 weeks for delivery.Ships in 1-2 Business Days

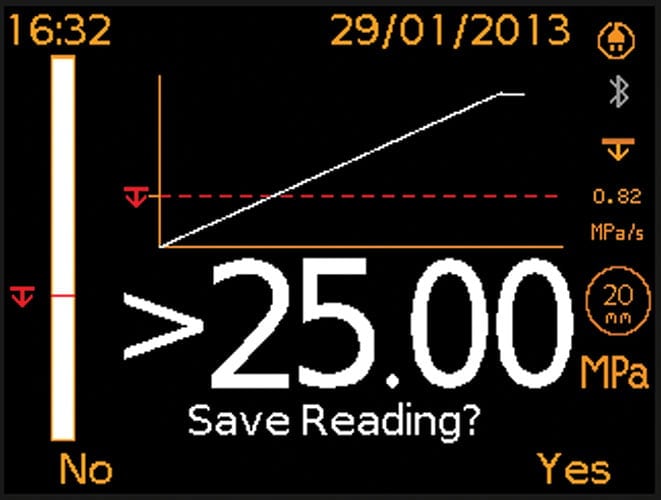

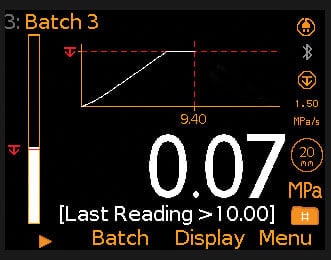

Product DescriptionThe Elcometer 510 Automatic Pull-Off Adhesion Tester accurately measures the strength of the bond between the coating and the substrate. - Automatic hydraulic pump ensures smooth and continuous pressure application for consistent, repeatable results

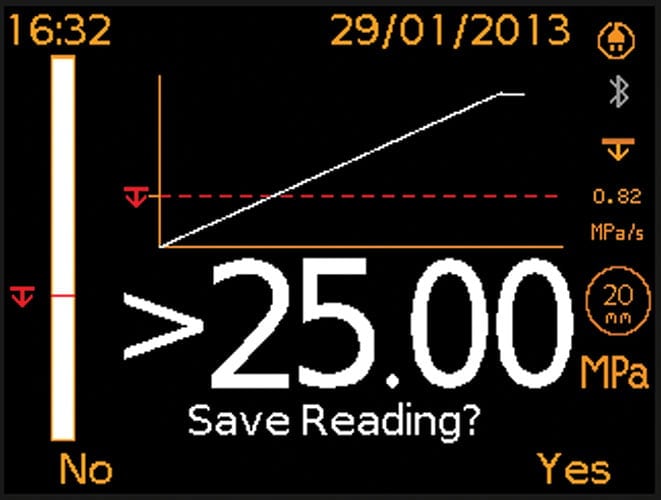

- Set adjustable pull rates @ 0.2, 0.3, 0.7, 1.0, 1.2 MPa/s(30, 50, 100, 150, 180psi/s)

- Can be used with 10, 14.2, 20 and 50mm diameter dollies

- User definable limits with unique pressure hold and release function

- User definable measurement range with an accuracy of ±1% of full scale:

- 10mm dolly: 14400psi (100MPa)

- 14.2mm dolly: 7200psi (50MPa)

- 20mm dolly: 3600psi (25 MPa)

- 50mm dolly: 580psi (4MPa)

- Dust and water resistant rugged design to IP64

- Interchangeable units: MPa, psi, Nmm2 and N

- A range of standard and thin substrate actuator skirts (compatible with Elcometer 506) available for testing coatings on thick, thin, flat or convex substrates

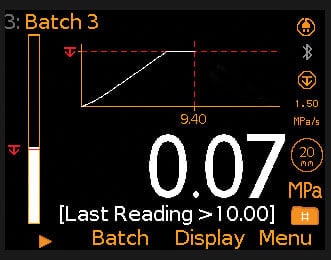

- Store up to 60 readings

- USB data output

| Key Features Explained |  |  |  | | Automatic adhesion tester with selectable pull rates for 10, 14.2, 20 & 50mm diameter dollies. | View trend graphs or live statistics alongside the reading value. | Individual user definable pull rate graphs can be saved with each reading. |  |  |  | | Stores individual readings and pull rate graphs in up to 2,500 alpha numeric batches, together with date, time and attribute information. | Either pull to maximum or pull to preset limit. Unique time hold feature allows users to set a delay before pressure returns to zero. | Save cohesive and adhesive failure attributes alongside your adhesion pull data in accordance with National and International Standards. |  |  |  | | Powered by either standard rechargeable batteries or AC mains*. Each battery charge performs up to 200 pulls. Battery recharge time less than 300 minutes. | Transfer data to your PC via USB or Bluetooth® for further analysis with ElcoMaster™ software or view live pull rate graphs in ElcoMaster™ during the test. | Using wireless Bluetooth® communication link the gauge to an Android™ or iPhoneǂ mobile device. Live GPS coordinates from your mobile device can be added to reports and emailed instantly. |  |  |  | | A range of standard and thin substrate actuator skirts allow each gauge to be use with 10, 14.2, 20 or 50mm diameter reusable dollies, ideal for testing coatings on thick, thin, flat or convex substrates. | The optional magnetic anchor clamp ensures the actuator doesn't fall during tests on vertical surfaces or testing at height. | Supplied in a robust plastic carry case for easy transportation to and around the job site. |

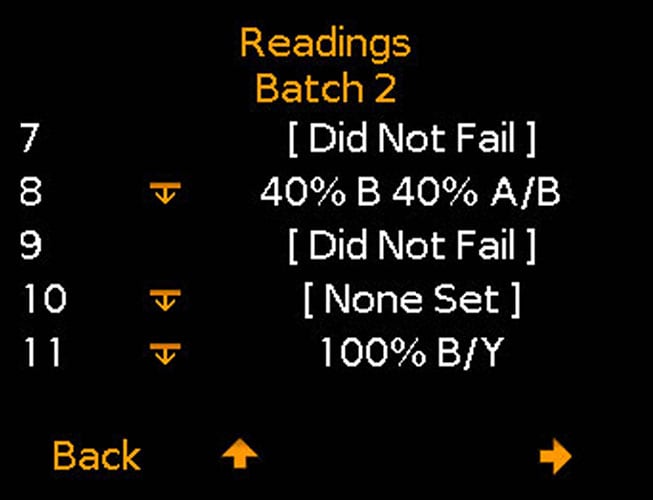

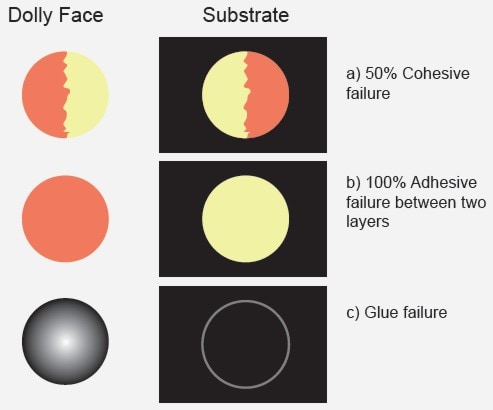

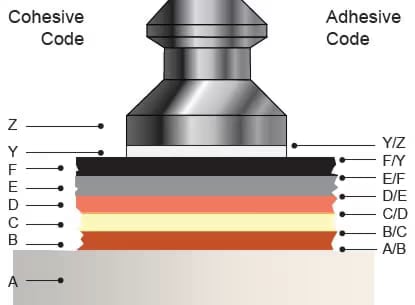

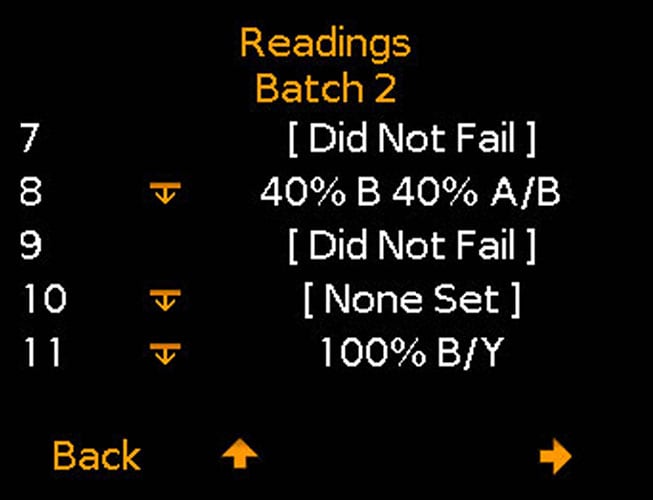

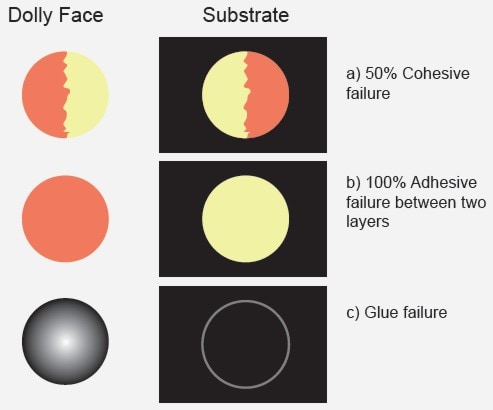

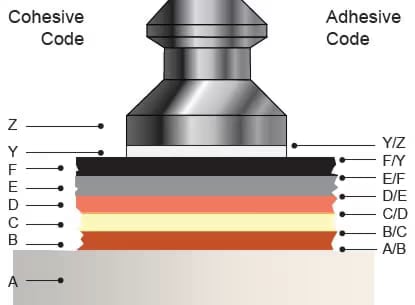

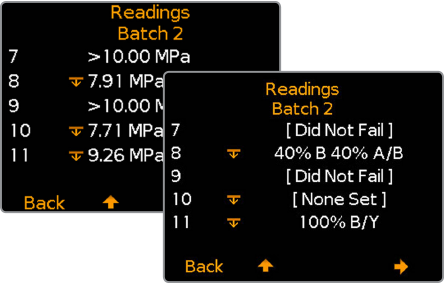

* Model T only. ǂ iPod, iPhone and iPad compatible Assessing The Results - Failure Attributes | Many National and International Standards, including ISO 4624 & ASTM D4541, require the user to record not only the pull-off force but also the nature of the failure. This is done by examining the bottom of the dolly and assessing the failure. In 'Advanced' mode on the Elcometer 510 it is possible to select the 'Attributes' feature (Menu/Setup/Gauge Mode/Advanced) allowing the nature of the fracture to be recorded against each reading and stored within the batch. | Examining The Dolly |  | a) Cohesive Failure: The coating fails within the body of a coating layer leaving the same coating on the surface and on the dolly face. | b) Adhesive Failure: Failure occurs at the interface between layers (intercoat) where one pulls away from the other. The “coating” on the dolly face will not be the same as that on the test area. | c) Glue Failure: When no coating is present on the dolly it must be recorded as a failure of the glue. This maybe due to incorrect or insufficient mixing of the component parts of the adhesive, incompatibility between the adhesive/coating/dolly/test surface. | | Cohesive Failure Layerd | Adhesive Failure Layers |

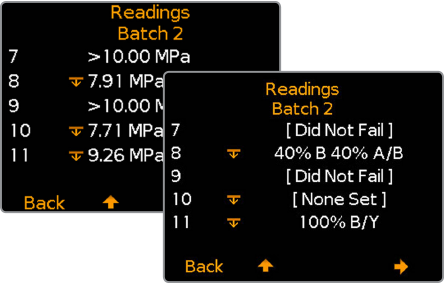

| Code | Description | Code | Description | | A | Substrate | A/B | Substrate & Layer 1 | | B | Layer 1 | B/C | Layer 1 & Layer 2 | | C | Layer 2 | C/D | Layer 2 & Layer 3 | | D | Layer 3 | D/E | Layer 3 & Layer 4 | | E | Layer 4 | E/F | Layer 4 & Layer 5 | | F | Layer 5 | F/Y | Layer 5 & Glue | | Y | Glue | Y/Z | Glue & Dolly | The data is saved in the batch and can be viewed at any time displayed as ##.## MPae N% A M% A/B, where; ##.## MPae = Pull Force in MPa or other measurement units (psi, Newtons or Nmm-2) N% = Cohesive failure percentagef A = Cohesive failure layer M% = Adhesion failure percentagef A/B = Intercoat adhesive failure layers |

| d The number of layers can be user defined for each batch via Batch/New Batch/Number of Layers. This will affect the number of layers available for selection during attribute recording. The maximum number of layers available is five, excluding the substrate and glue. e Or equivalent units. f To the nearest 10%, in line with International Standards. |

| The new ElcoMaster™ 2.0 is a fast, easy to use software solution for all your reporting requirements. Click the icons below for more information. |  |  |  |  |  |  |

Elcometer 510 Model T: Made for iPhone 5S, iPhone 5C, iPhone 5, iPhone 4S, iPhone 4, iPad (4th generation), iPad mini, iPad 2, and iPod touch (4th and 5th generation).“Made for iPod,” “Made for iPhone,” and “Made for iPad” mean that an electronic accessory has been designed to connect specifically to iPod, iPhone, or iPad, respectively, and has been certified by the developer to meet Apple performance standards. Apple is not responsible for the operation of this device or its compliance with safety and regulatory standards. Please note that the use of this accessory with iPod, iPhone, or iPad may affect wireless performance. iPad, iPhone, and iPod touch are trademarks of Apple Inc., registered in the U.S. and other countries. App Store is a trademark of Apple Inc., registered in the U.S. and other countries. All other trademarks acknowledged. Mobile Devices running Android software version 2.1 and upwards.

|

|

|

|