Related Product(s)>> Related Product(s)>>

>>Download Full PDF

The Elcometer 510 Automatic Pull-Off Adhesion Gauge accurately measures the strength of the bond between the coating and the substrate.

Key Features Explained

| Automatic adhesion tester with selectable pull rates for 10, 14.2, 20 & 50mm diameter dollies. |

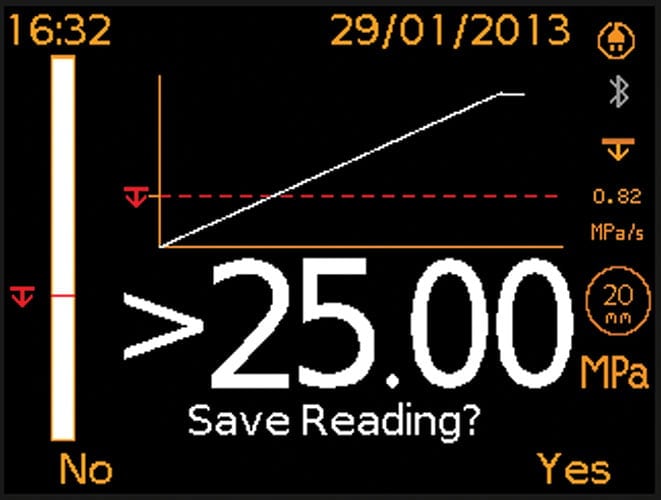

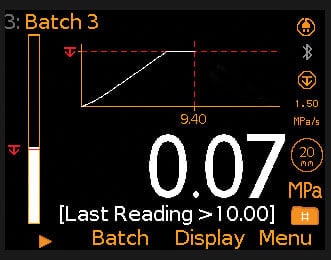

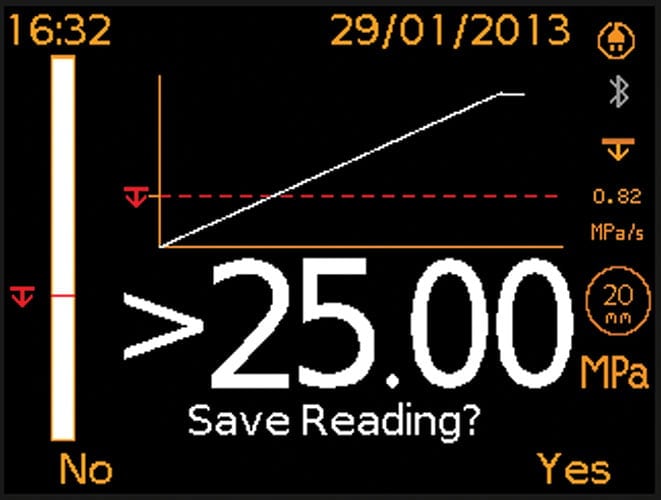

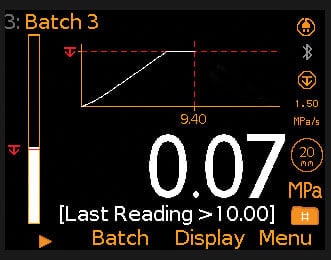

| View trend graphs or live statistics alongside the reading value. |

| Individual user definable pull rate graphs can be saved with each reading. |

| Stores individual readings and pull rate graphs in up to 2,500 alpha numeric batches, together with date, time and attribute information. |

| Either pull to maximum or pull to preset limit. Unique time hold feature allows users to set a delay before pressure returns to zero. |

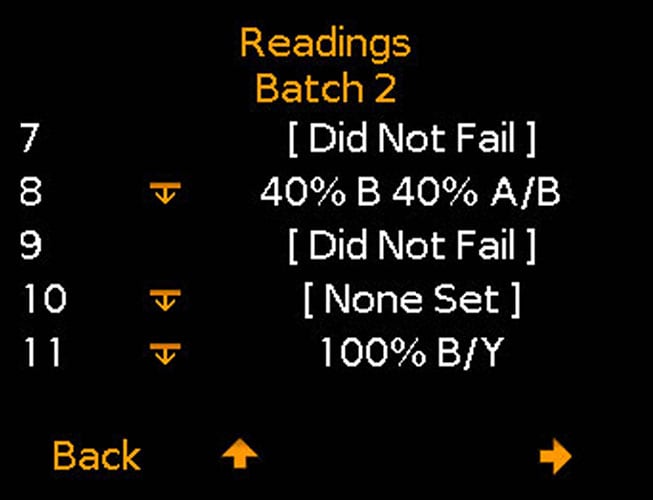

| Save cohesive and adhesive failure attributes alongside your adhesion pull data in accordance with National and International Standards. |

| Powered by either standard rechargeable batteries or AC mains*. Each battery charge performs up to 200 pulls. Battery recharge time less than 300 minutes. |

| Transfer data to your PC via USB or Bluetooth® for further analysis with ElcoMaster™ software or view live pull rate graphs in ElcoMaster™ during the test. |

| Using wireless Bluetooth® communication link the gauge to an Android™ or iPhoneǂ mobile device. Live GPS coordinates from your mobile device can be added to reports and emailed instantly. |

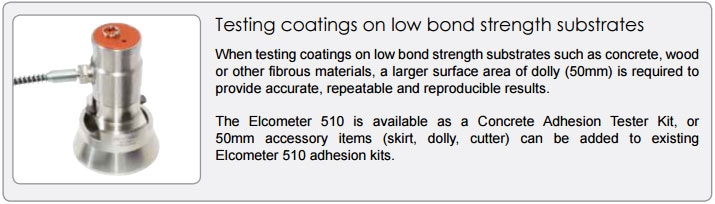

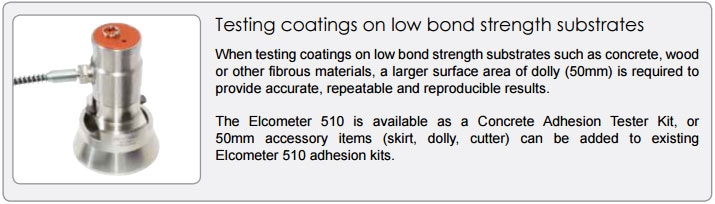

| A range of standard and thin substrate actuator skirts allow each gauge to be use with 10, 14.2, 20 or 50mm diameter reusable dollies, ideal for testing coatings on thick, thin, flat or convex substrates. |

| The optional magnetic anchor clamp ensures the actuator doesn't fall during tests on vertical surfaces or testing at height. |

| Supplied in a robust plastic carry case for easy transportation to and around the job site. |

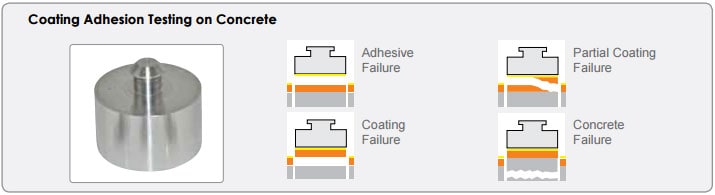

Assessing The Results - Failure Attributes

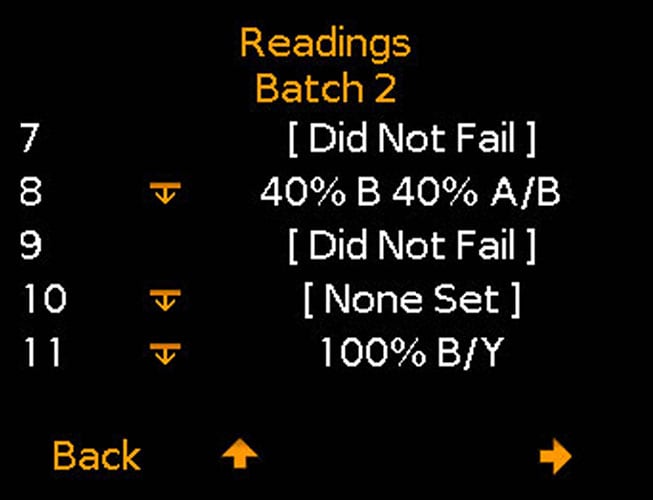

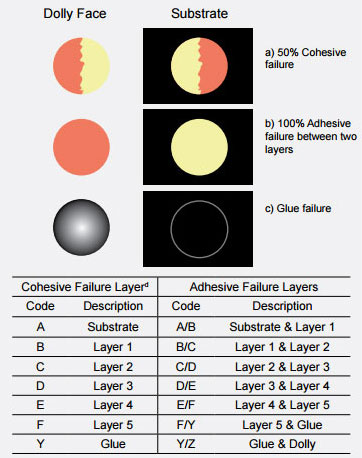

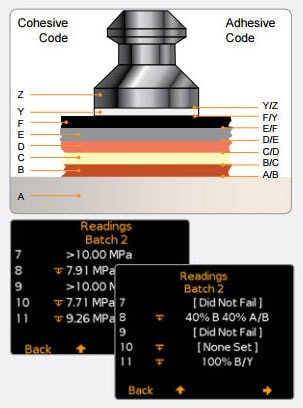

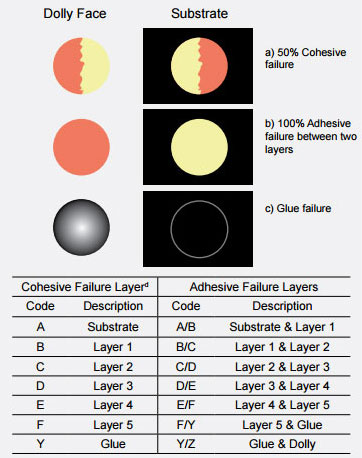

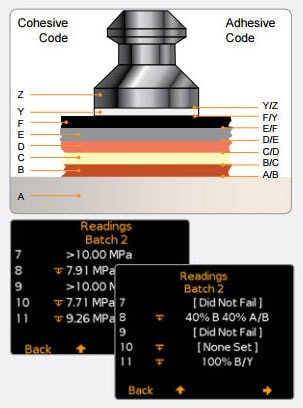

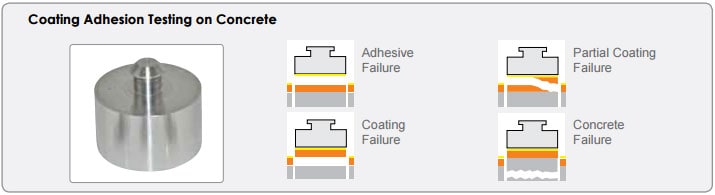

Many National and International Standards, including ISO 4624 & ASTM D4541, require the user to record not only the pull-off force but also the nature of the failure. This is done by examining the bottom of the dolly and assessing the failure. In ‘Advanced’ mode on the Elcometer 510 it is possible to select the 'Attributes' feature (Menu/Setup/ Gauge Mode/Advanced) allowing the nature of the fracture to be recorded against each reading and stored within the batch.

Examining The Dolly

a) Cohesive Failure: The coating fails within the body of a coating layer leaving the same coating on the surface and on the dolly face.

b) Adhesive Failure: Failure occurs at the interface between layers (intercoat) where one pulls away from the other. The “coating” on the dolly face will not be the same as that on the test area.

c) Glue Failure: When no coating is present on the dolly it must be recorded as a failure of the glue. This may be due to incorrect or insufficient mixing of the component parts of the adhesive, incompatibility between the adhesive/coating/dolly/test surface.

| ##.## MPae | N% A M% A/B, where; |

|---|

| ##.## MPae | = Pull Force in Mpa or other measurement units (psi, Newtons or Nmm-2) |

| N% | = Cohesive failure percentagef |

| A | = Cohesive failure layer |

| M% | = Adhesion failure percentagef |

| A/B | = Intercoat adhesive failure layers |

Create instant reports with ElcoMasterTM

Whether you are out in the field or on the factory floor, using the ElcoMaster™ Mobile App users can:

- Store live readings directly on to a mobile device and save them into batches.

- View the pull rate graph in real-time for the duration of the test.

- Add attribute data to each individual batch reading.

- Add photographs of the dolly and test surface to each individual batch reading at the click of a button.

- Plot individual readings on to a location map, photograph or diagram.

- Inspection data can be transferred from mobile to PC for further analysis and reporting.

- Generate instant .pdf report for submission.

Data transferred from the gauge to ElcoMaster™ includes:

- Adhesion Measurements

- Date & Time

- Cohesive/Adhesive Failure Attributes

- Dolly size

- Pull rate graph

- Pull to Limit/Max

- Limit values

- Limit Hold Time

- Cutting Device

- Number of Layers

- Skirt Type/Support Ring Dimensions

- Batch Information & Statistics

- Calibration Information

- Calibration Verification Date/Time

Product Features | | Model S | Model T | Repeatable & reproducible measurements | • | • | Easy to use menu structure; multiple languages | • | • | Tough, impact, waterproof & dust resistant; equivalent to IP64 | • | • | Bright LCD colour screen; with ambient light sensor | • | • | Scratch & solvent resistant display; 2.4” (6cm) TFT | • | • | Calibration certificate | • | • | 2 year gauge warranty | • | • | Automatic rotating display; 0°, 180° | • | • | Data output via USB (Live readings - and batch) | • | • | Data output via Bluetooth® | | • | PC command; start & stop gauge from a PC with live readings (USB only) | | • | Switchable Units (mPa, psi, N, Nmm-2) | • | • | On-Screen Statistics (η, x, σ, hi, lo, COV, N>hi limit♦) | • | • | Trend Graph | • | • | Pull Rate Graph (Load v Time) | | • | Interchangeable Dolly Selection; 10, 14.2, 20 & 50mm | • | • | User Selectable Pull Rates; (Model S & Model T Standard Mode)+ | | | 10mm: 1.00, 2.00, 3.00, 4.00, 5.00 MPa/s 14.2mm: 0.4, 0.7, 1.4, 2.0, 2.5 MPa/s

20mm: 0.2, 0.3, 0.7,1.0, 1.2 MPa/s

50mm: 0.04, 0.08, 0.12, 0.16, 0.20 MPa/s | 125, 200, 400, 600, 725psi/s 60, 100, 200, 300, 360psi/s 30, 50, 100, 150, 180psi/s 5, 8, 16, 24, 30psi/s | • | • | User Selectable Pull Rates; (Model T Advanced Mode)+ | | | 10mm: 0.4 - 5.60 MPa/s 14.2mm: 0.2 - 2.80 MPa/s 20mm: 0.1 - 1.40 MPa/s

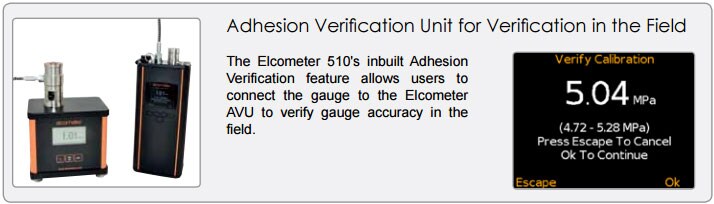

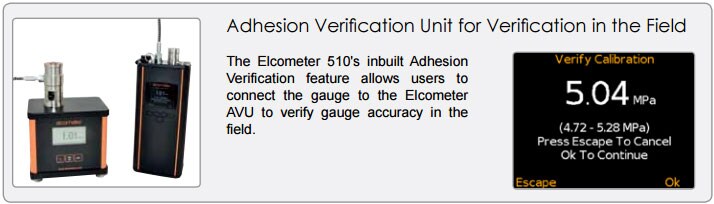

50mm: 0.02 - 0.22 MPa/s | 58 - 812psi/s 29 - 403psi/s 15 - 203psi/s 2 - 32psi/s | in 0.1MPa / 1psi steps in 0.1MPa / 1psi steps in 0.1MPa / 1psi steps in 0.01MPa / 0.1psi steps | | • | User Selectable Limit & Limit Hold Time | | • | Gauge Memory; maximum number of readings | 60 | 60,000* | Number of Batches (Alpha Numeric - Model T) | 1 | 2,500 | Attribute Modes to meet National & International Standards | | • | Display Modes | | | Readings, Selected Stats & Run Chart (last 20 readings) | • | • | Pull Rate Graphs | | • | Batch Review | | • | Power; Battery (B), AC Mains Power (M) | B | B, M | USB Cable & ElcoMaster™ 2.0 CD | • | • | Power Cable with Multi International Plug Adaptor (UK, EU, US, AUS) | | • | Plastic Transit Case | | • | Date & Time | | • | In Field Adhesion Calibration Verification Mode | | • |

Technical Specification

Part Number | Description | Certificate | F510-20S | Elcometer 510 Model S Automatic Adhesion Gauge; 20mm Kit | • | F510-20T | Elcometer 510 Model T Automatic Adhesion Gauge; 20mm Kit | • | F510-50S | Elcometer 510 Model S Automatic Adhesion Gauge; 50mm Concrete Kit | • | F510-50T | Elcometer 510 Model T Automatic Adhesion Gauge; 50mm Concrete Kit | • | Pressure Accuracy | ±1% of full scale | | Pull Rate Accuracy | ±(2.5% + 0.3 seconds) | Pressure Resolution | 0.01MPa (1 psi) | | Pull Rate Resolution | 0.01MPa (1psi/s) | Dolly Diameter | 10mm (0.39") | 14.2mm (0.56") | 20mm (0.76") | 50mm (1.96") | Operating Range | 8 to 100 MPa

(1200 to 14400 psi) | 4 to 50 MPa

(600 to 7200 psi) | 2 to 25 MPa

(300 to 3600 psi) | 0.3 to 4 MPa

(50 to 580 psi) | Pull Rate Range | 0.4 - 5.6MPa/s

(58 - 812psi/s) | 0.2 - 2.8MPa/s

(29 - 403psi/s) | 0.1 - 1.4MPa/s

(15 - 203psi/s) | 0.02 - 0.22MPa/s

(2 - 32psi/s) | Gauge Dimensions | 260 x 100 x 66mm (6.3 x 3.9 x 2.6") | Actuator Height | 85mm (3.4") | 85mm (3.4") | 85mm (3.4") | 110mm (4.3") | Instrument Weight | 2.9kg (6.4lb) | 2.9kg (6.4lb) | 2.9kg (6.4lb) | 3.1kg (8.3lb) | Kit Weight | - | - | 6.1kg (13.5lb) | 7.3kg (16.1lb) | Power Supply | 8 x AA NiMH/Alkaline batteries (16 rechargeable batteries supplied complete with charger) or AC mains power (Model T only) | Battery Life | ~200 pulls per charge up to 25MPa (3600psi) at 1MPa/s (150psi/s), recharge time less than 5 hours | Packing List: 20mm Kit | Elcometer 510 Adhesion Tester with 20mm dollies (x10), standard skirt for 20mm dollies, 20mm dolly cutter handle, 20mm dolly cutter, Araldite standard two part epoxy adhesive (2 x 15ml tubes), abrasive pad, shoulder harness, carry case, 16 x AA MiMH rechargeable batteries & charger (UK, EU, US, AUS), mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster™ CD & USB cable, calibration certificate and operating instructions. | Packing List: 50mm Kit | Elcometer 510 Adhesion Tester with 50mm dollies (x6), standard skirt for 50mm dollies, 50mm dolly cutter arbor, 50mm dolly cutter, Araldite standard two part epoxy adhesive (2 x 15ml tubes), abrasive pad, shoulder harness, carry case, 16 x AA MiMH rechargeable batteries & charger (UK, EU, US, AUS), mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster™ CD & USB cable, calibration certificate and operating instructions. |

Pull-Off Adhesion Tests - Preventing Adhesive and Cohesive Failures

Preparing the surface and dolly

- Select an appropriate test area which is flat and has sufficient area to attach the adhesion gauge.

- Abrade the dolly and surface, clean both to remove any dust - minimizing the rish of an 'adhesive' failure.

Fixing the dolly

- Mix the adhesive correctly and apply a uniform adhesive film over the entire dolly face.

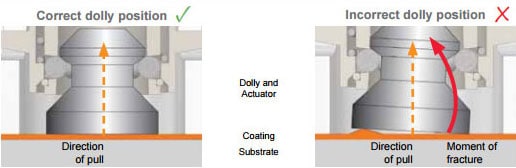

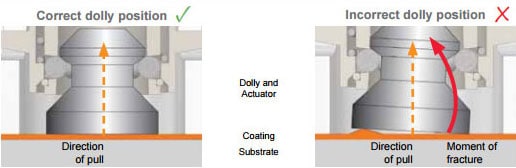

- Test Standards require that the dolly is pulled off perpendicularly to test surface. The dolly must therefore be adhered on to a prepared flat test surface (see images below). Apply an even pressure to the dolly to ensure that the dolly face is parallel to the test surface.

- Remove any excess adhesive from around the dolly and allow to fully cure. Tape may be required when applying dolies to vertical surfaces during the cure process.

- If required, once the dolly has fully cured, score the coating around the dolly using the dolly cutter provided.

- Attach the gauge actuator to the dolly and begin test.

Assessment of the Adhesion Test

For a valid pull test the coating must cover at least 50% of the area of the dolly face. If the glue fails and no coating is

present on the dolly, or it covers less than 50% of the dolly face area, the pull-test is invalid and should be repeated.

When the coating has failed within the layer leaving the same coating on both the dolly and the test panel it is known

as a ‘cohesive failure’.

‘Adhesive failures’ occur when either the coating has failed at the interface with another coating (leaving a coating on the dolly and another coating on the substrate), or when the coating has failed at the substrate (leaving the

coating on the dolly and the substrate is bare).

NOTE: If the glue fails at a value above the specification then it can be reported that the adhesion exceeded the

specification for this individual test.

Related Product(s)Download Full PDF |